Background

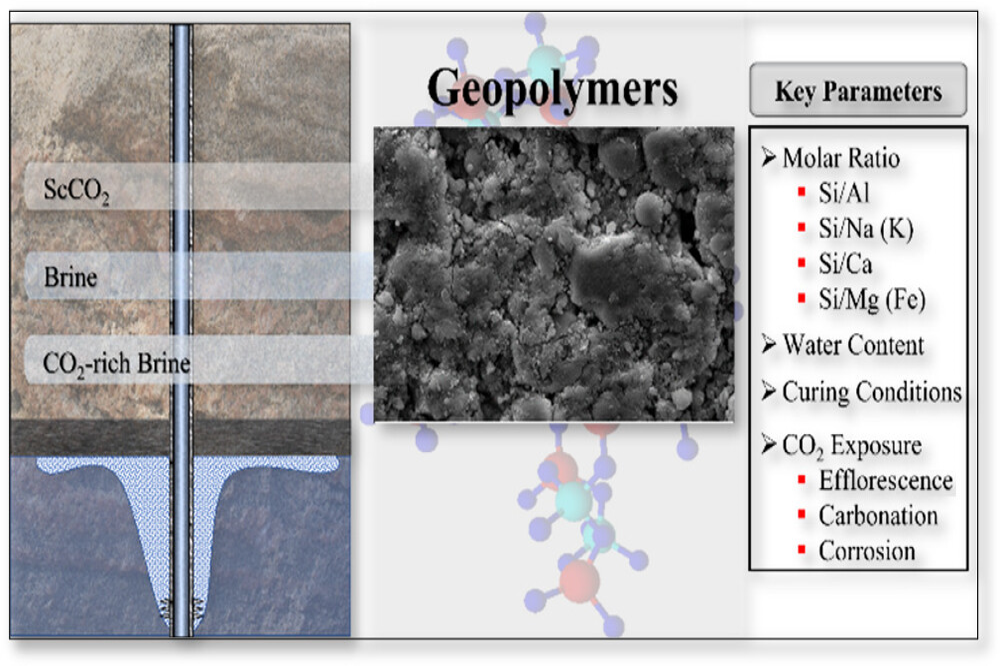

Climate change is now a global health and security challenge. Energy transition from fossil fuels to green energy is one of the topmost priorities of the government of Ghana. The storage of CO2 in underground geologic formation such as deep saline reservoirs and depleted oil and gas fields is one proven means of reducing CO2 emissions. Ordinary Portland cement (OPC) is generally used in the formulation of the sealant to prevent the leakage of the gas back into the atmosphere. Unfortunately, the production of OPC is a major contributor to CO2 emission. Additionally, OPC-based systems have poor durability in CO2 environment, the gas reacts with the material and eventually leaks through it. Geopolymers are cement systems that have been explored as alternative to OPC-systems, especially for sealing CO2 and other corrosive gas wells. However, the proposed two-part geopolymer systems have several drawbacks. In this project, carbon carbide residue (CCR), a waste material from the hydrolysis of calcium carbide will be used to develop a one-part geopolymer that can be mixed with water to seal CO2 wells efficiently.

Objectives

- To test the durability of the developed geopolymer under static CO2 environment.

- To develop a protocol and plant design for the commercial production of the material.

Proposed Method

- Characterization of Raw Materials using analytical methods such as XRD and XRF

- Slurry formulation and testing: rheology, thickening time

- Curing of formulation

- Carbonation test

- Durability test