The CO2 Storage Resource Assessment Project (CO2SRAP)

Energy transition is now one of the topmost priorities of the oil and gas industry. According the IEA, the oil and gas industry accounts for about 45% of global Greenhouse Gas (GHG) emissions. To achieve realistic energy transition and sustain the production of fossil fuels, the petroleum industry must play a leading role to decarbonize its operations and support climate initiatives. Carbon Capture Utilization and Storage (CCUS) is the most viable option for decarbonizing the oil and gas industry. The main prerequisite for deployment of CCUS is the availability of viable, safe and secure geological storage facilities. Ghana is blessed with at least four sedimentary basins that could be deployed as suitable formations for CO2 storage. But these storage facilities must be identified and properly assessed to determine their storage potential. This project will identify, screen, score and rank geological storage facilities in Ghana in terms of their CO2 storage prospectivity to develop a preliminary CO2 Storage Resource Database for the country and prepare a knowledge gap score card to direct data mobilization towards a more robust assessment in future.

Learn More

The CO2 Transport Efficiency in Pipelines (CO2TRANSEP) Project for CCUS through Modelling and Experimentation

The increasing concentration of carbon dioxide (CO2) in the atmosphere poses a significant threat to the global climate. Carbon Capture, Utilization, and Storage (CCUS) is a critical strategy to mitigate CO2 emissions from industrial processes. Efficient transportation of captured CO2 through pipelines is a key component of successful CCUS implementation. However, challenges such as pipeline corrosion, pressure drops, and energy consumption need to be addressed to ensure the safe and cost-effective transport of CO2.

Learn More

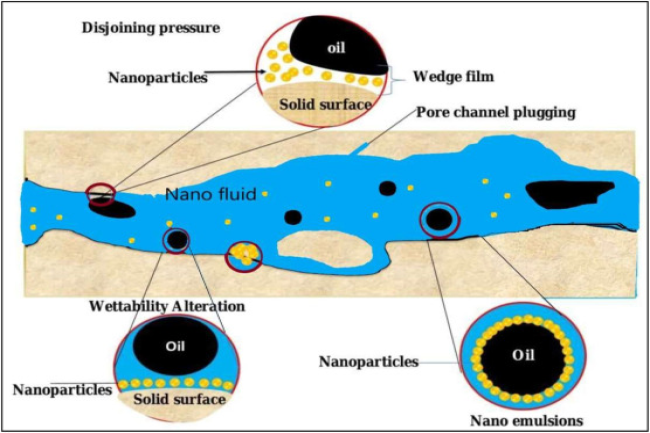

Formulation of a biosurfactant based nanofluid for chemical enhanced oil recovery in high temperature high salinity reservoirs

Chemical enhanced oil recovery (cEOR) faces significant challenges. One of the reasons is the availability, or lack of, compatible chemicals in high temperature and high salinity (HTHS) environments. Also, application of traditional cEOR methods is limited by high cost and the fact that these chemicals cause environmental pollution when spilled. In line with Sustainable Development Goals (SDGs) 6, 14 & 15, it is imperative to formulate an environmentally friendly surfactant which is cheap for application in high temperature high salinity reservoirs. Therefore, this project seeks to identify plants with naturally high saponins, extract these saponins and formulate a fluid in synergy with nanoparticles. The prepared biosurfactant based nanofluid will then be characterized and optimized. The optimized biosurfactant based nanofluids will be subjected to high temperature high salinity conditions and the most stable fluid selected for core flooding to determine the ultimate recovery factor. A guiding document will be prepared on the formulated biosurfactant based nanofluid with innovative guidelines to stimulate interest from industry to adopt it. Pilot field tests is proposed for the formulated fluid to be tried in cEOR.

Learn More

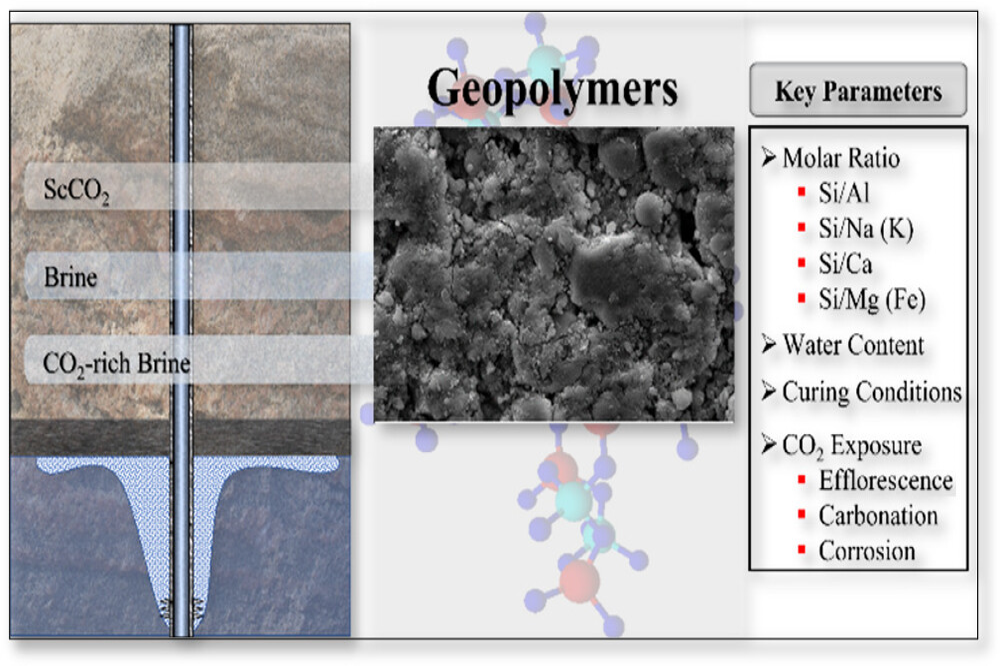

Development of One-part Geopolymer as a Novel Sealant for CO2 Sequestration Wells to achieve a NetZero Greenhouse Gas Emission in Ghana

Climate change is now a global health and security challenge. Energy transition from fossil fuels to green energy is one of the topmost priorities of the government of Ghana. The storage of CO2 in underground geologic formation such as deep saline reservoirs and depleted oil and gas fields is one proven means of reducing CO2 emissions. Ordinary Portland cement (OPC) is generally used in the formulation of the sealant to prevent the leakage of the gas back into the atmosphere. Unfortunately, the production of OPC is a major contributor to CO2 emission. Additionally, OPC-based systems have poor durability in CO2 environment, the gas reacts with the material and eventually leaks through it. Geopolymers are cement systems that have been explored as alternative to OPC-systems, especially for sealing CO2 and other corrosive gas wells. However, the proposed two-part geopolymer systems have several drawbacks. In this project, carbon carbide residue (CCR), a waste material from the hydrolysis of calcium carbide will be used to develop a one-part geopolymer that can be mixed with water to seal CO2 wells efficiently.

Learn More

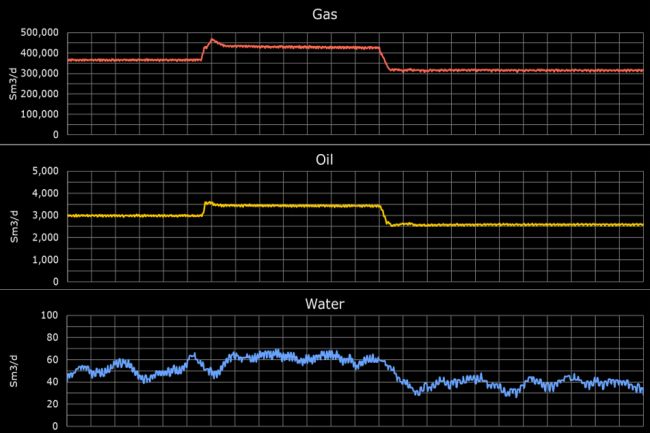

Virtual Flow Metering (VFM) for Enhanced Flow Measurement in Ghana's Oil and Gas Industry

As Ghana's oil and gas industry continues and seeks to expand, the accurate measurement of fluid flow is crucial for effective production surveillance and monitoring. Conventional flow metering systems are often expensive and face challenges in maintaining accuracy in diverse operating conditions. More so, given the recent reduction in gross production in the last few years , accuracy and reliable measurements are key elements required to understand the bottlenecks that face the industry. This project proposes the implementation of Virtual Flow Metering (VFM) technology as an innovative and cost-effective solution to address these challenges, providing accurate real-time flow measurements for production surveillance in Ghana's oil and gas sector.

Learn More

Net-Zero Emissions Tracking System (NETS) for the Oil and Gas Industry

To meet its nationally determined contribution to the Paris Agreement, the government of Ghana aims to reduce GHG emissions by at least 15% by 2030 with a more ambitious goal to attain net-zero emissions by 2070. To meet this emission reduction targets, the oil and gas industry, which is responsible for almost half of global anthropogenic GHG emissions must demonstrate a commitment to decarbonize its operations and support climate initiatives. Locally, individual companies in the oil and gas industry report their GHG emissions to the Petroleum Commission (PC) and publish their climate actions in their annual reports. But the industry is not getting the required credit for its emission reduction investments because, while the carbon footprint of the industry has been widely publicised, the mitigation efforts are not readily accessible in the form that the public and global partners can process and understand. The industry need a system to harmonize all emission and mitigation data from its major players onto a common platform for effective dissemination to change public perfection towards the industry while encouraging more climate action.

Learn More

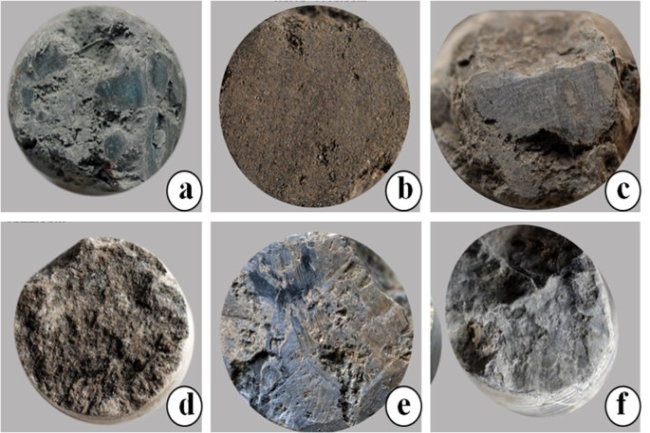

The Biogenic Reservoir Rock Quality Characterization Project (TBRRQCP)

Burrowing activity by organisms alters textural characteristics and diagenetic effects of the substrate, which can result in partial or complete removal of occurring substrate structures and alter sorting. The burrows produced by these organisms contain sediments that are lithological and geochemically distinct from the matrix. The result can cause an increment or reduction in burrow porosity and permeability as compared to the surrounding matrix Organism-substrate interaction has crucial control over reservoir quality. Thus, the ichnological analysis of bioturbated reservoir facies is integral to reservoir characterization. In Ghana, the effect of biogenic activity on reservoir rock quality is under reached; there are no publications concerning this subject. Coupled with a lack of financial support from the industry, our investigations show that there is inadequate sensitization of researchers/students and unavailable laboratory resources. In other countries, relevant universities have received financial support to investigate, characterize, and publish the results of this very important subject matter.

Learn More

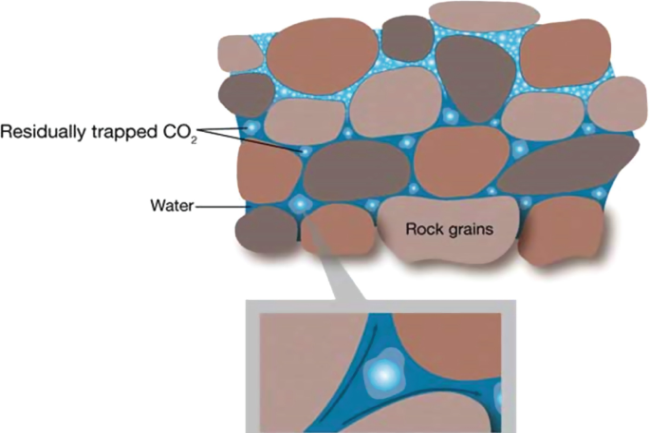

Geochemical Evaluation of Rock/Brine/CO2 Interaction during CCS

Carbon Capture and Storage is an inevitable technique of mitigating the hazardous effect resulting from carbon emission to the environment. Nonetheless, the effect of the sequestered CO2 on the rock with time needs to be fully understood. Experimental and geochemical modelling will be employed in this work. The rock-formation water will be aged first before injecting the CO2. This is to mimic the state of the rock-brine prior to the CO2 injection. The rock-fluids (i.e. brine and CO2) interactions are evaluated with time to assess the effect of the sequestered CO2. This will be carried-out using different minerals, mineral mixtures, rock samples and fluid samples. The rock-fluids system will also be modelled using a geochemical simulator (PHREEQ-C). The experimental results and the simulated counterpart will be compared before drawing conclusions.

Learn More

Formation Damage Assessment and Mitigation (FDAM) Project

Formation damage problems are one of the most expensive technical and operational challenges of oil and gas production. Ensuring an uninterrupted flow of hydrocarbon fluids from the reservoir into the production facilities is key for operation and profitability. Poor understanding and management of formation damage issues can result in production and process downtime, safety incidents and loss of revenue. It is estimated that just 1% of unplanned downtime or 3.65 downtime days per year can cost companies up to USD 5 million each year. Based on a global average downtime of just over 27 days per year, offshore oil and gas companies could incur a huge financial loss in the regions of USD 38 million, all things been equal. If formation damage risks are understood and addressed early, significant OPEX can be saved. Most companies have struggled to find plausible solutions to common damage challenges because they have often relied on the experience of field engineers to find temporary interventions. The FDAM project will establish a multidisciplinary team of researchers to conduct a thorough investigation of common formation damage challenges in the local oilfields and design unique mitigation options to the problems.

Learn More

Sustainable Materials for Oilfield Wastewater Treatment (SMOWT)

Oilfield produced water is the largest volume waste stream associated with oil and gas production. Increasingly stringent environmental regulations require extensive treatment of produced water before disposal. Currently, treatment and disposal of oilfield wastewater alone costs the global oil and gas industry more than USD 40 billion annually. Apart from the high CAPEX investment required to setup an efficient treatment system, the main OPEX is associated with the cost of maintenance, energy and chemicals. Ghana is blessed with abundant biomass resources, clay deposits and other raw materials that can be used as feedstock to produce commercial quantities of sustainable oilfield materials. However, currently, almost all the major materials, chemicals and agents used in oilfield wastewater treatment in Ghana are imported. The SMOWT project will design, test, standardize and commercialize the production of at least two sustainable materials for oilfield wastewater treatment in Ghana.

Learn More

Assessment of Cap Rock Competency for CO2 Storage

The oil and gas industry has made the energy transition a primary focus. The International Energy Agency (IEA) notes that this sector contributes approximately 45% of the world's total Greenhouse Gas (GHG) emissions. The effectiveness of a CCS (carbon capture and storage) initiative is closely tied to how the public views its potential to significantly reduce industrial carbon emissions on a large scale. Displaying proficiency in storing effectively relies on the capacity to oversee the surroundings and forecast the movement and mechanics of the reservoir before, during, and after injection. A successful CCS heavily relies on the stability of the cap rock and the accuracy in modeling and anticipating subsurface shifts and CO2 movement using numerical and analytical models across various timeframes, be it short or long-term. This project seeks to conduct geomechanical and petrographic studies that can aid the assessment of cap rock integrity and facilitate the monitoring or mitigation of CO2 migration above the cap rock.

Learn More